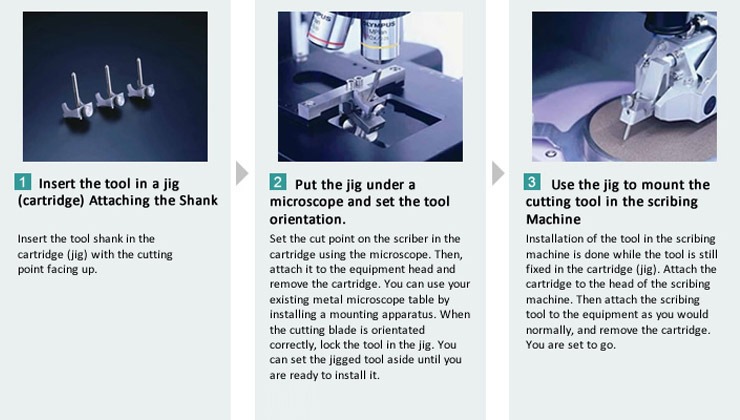

The shape of the tool tip must be set in the correct alignment for scribing the wafer. Since the tip is microscopic in size it is difficult to see the tip or to determine the cutting point of the scribing tool. It is cumbersome for an operator to make these adjustments with the naked eye or by using low magnification devices. Additionally, it is necessary to use a sample wafer in order to perform scribing tests to ensure the cuts are within the specification. This process is traditional in the sense that it required a lot of the operator’s time and the results depended heavily on that operator’s skill.

This alignment system allows operators to easily and consistently locate cutting points to greatly improve the consistency of quality.

In addition, the “changeover time,” or the downtime needed to prepare equipment for scribing, is dramatically decreased. Off-line tool setting allows more efficient scheduling of processes as well as efficient operator training.

+1-408-748-0100

+1-408-748-0100

Office Hours: 8:30am - 5:30pm PST