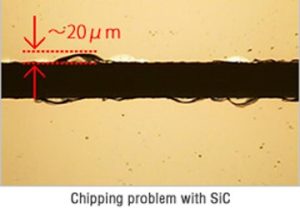

Silicon carbide (SiC) is the third hardest compound on the face of the earth, coming in at number 13 on the revised Mohs scale. Only diamonds and boron carbide (15 and 14 on the revised Mohs scale) are harder. Being so high on the Mohs scale makes dicing SiC wafers a difficult challenge. Cutting with a saw blade is slow, tedious, and can generate a lot of heat. Since the material is also brittle, chipping is also a common problem. Cutting with laser also has its own challenges such as debris and the fact that the machine is very expensive.

Because silicon carbide wafers are extremely hard and brittle, singulation is exceedingly slow and prone to excessive die edge chipping, which makes economical mass production difficult. The tools are also very expensive to replace. In order for semiconductor manufacturers to move from the SiC device development stage to profitable mass production, these singulation problems needed to be solved.

Diced Sic wafer die sample produced by improved scribing technique

Not only do we singulate the sample wafer we receive from the client, we make it a point to discuss the specific results that are desired so that we can customize an existing product to your needs.

Tecdia’s new technology will enable a higher standard of quality and throughput than traditional saw dicing. Unsurprisingly, the equipment is also more economical than a laser scribe machine. There are several benefits to using our wafer scribing tools for SiC wafer singulation processing, and as scribing professionals it is our number one recommendation.

Wafer Scribing Machine

Manufacturers of SiC products have a new method of dicing wafers that produces high-yields at mass production rates.

+1-408-748-0100

+1-408-748-0100

Office Hours: 8:30am - 5:30pm PST