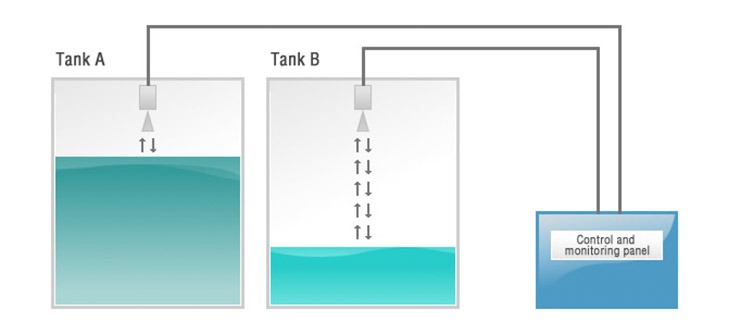

Petroleum comes in a variety of conditions and product types: from thin, clear liquids, like gasoline, to black, viscous, and heavy liquids like crude oil. A widely used method of monitoring fluid levels by using a float that goes to the surface of the fluid, indicating the level by its position, has been around for a long time. With this mechanical contact method, there are problems with highly viscous oils becoming stuck to moving parts and causing failures. Our client was looking for a solution that could easily be applied and adjusted.

Fluid Level Radar Unit

The new, easy to install, accurate and affordable monitoring system is very popular with our client.

+1-408-748-0100

+1-408-748-0100

Office Hours: 8:30am - 5:30pm PST