Reducing actuator manufacturing costs while improving quality.

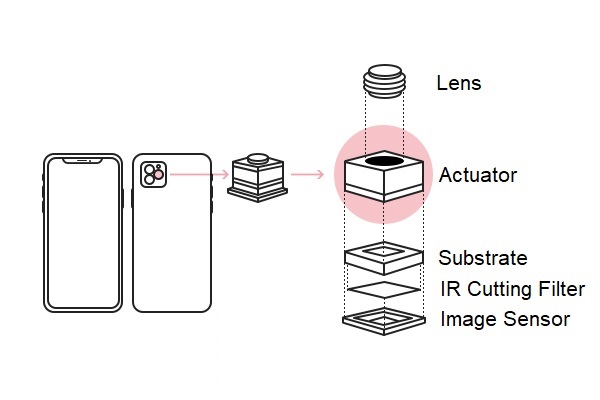

Smartphones are now equipped with high-precision dual cameras, triple cameras or even 5 lens cameras. This in turn increases the demand for camera actuators as a result of there now being a large number of cameras equipped on one smartphone, but at the same time, manufacturers are required to reduce manufacturing costs so as not to increase overall cost. One of the actuator assembly processes requires an adhesive to be applied using a dispensing nozzle. However, the cost of these dispensing nozzles, which are consumable items, was a consistent issue.

Providing built-to-spec nozzles that are approximately 30% less expensive than conventional products.

OEM dispensing nozzles sold as accessories to specific machines being used are commonly used for general dispensing applications. However, to reduce the cost of purchasing these dispensing nozzles, it is often necessary to shop around other manufacturers to get the best quality for a specific price target. However, deviating from specifications of a OEM product requires nozzles to be evaluated and takes time. This makes an inexpensive dispensing nozzle with the same specifications as the OEM product an ideal solution. Tecdia, which excels at customizing dispensing nozzles, has accurately achieved customer specifications and provided nozzles with a cost savings of approximately 30%.

Many manufacturers using dispensing nozzles for dispensing processes continue to use the OEM dispensing nozzles that come with the dispensing equipment.

However, customers who require better dispensing accuracy and lower manufacturing costs are advised to switch from OEM to Tecdia dispensing nozzles. There are three merits of switching. (1) Improved dispensing accuracy (2) Reduction of manufacturing costs (3) Longer service life of the dispensing nozzle. In fact, Tecdia has provided dispensing nozzles to various manufacturers (for camera modules, liquid crystal panels, etc.) for many years with great success.

Tecdia dispensing nozzles suppress clogging, creep-up and stringification of dispensed material due to the unique step-free internal shape and special nozzle tip processing.

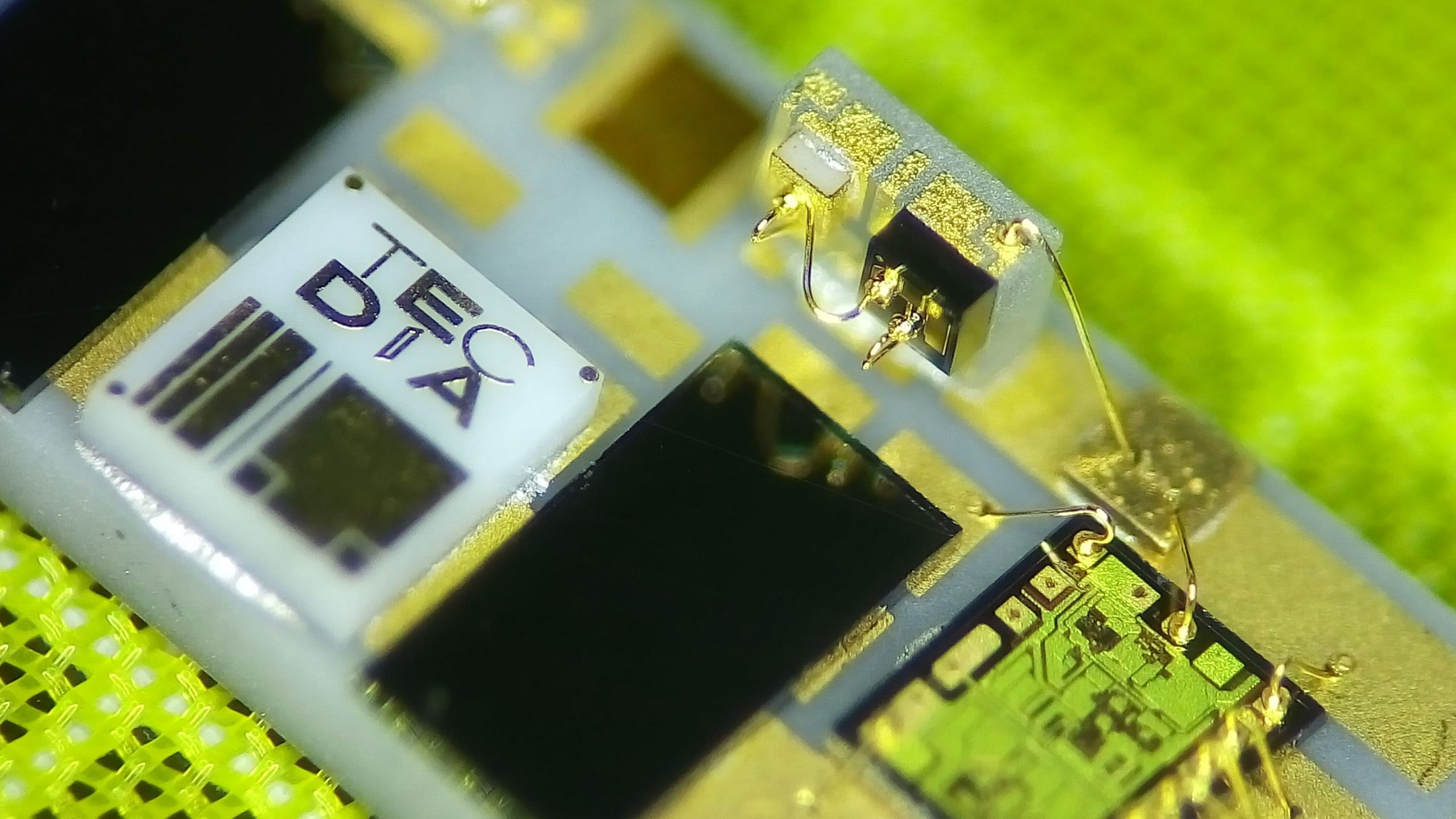

Tecdia nozzles were adopted by a major actuator manufacturer thanks for the ability to accurately realize the specifications required by the customer at a reasonable cost.

We are also taking the onus of preparing technical proposals for changes to the specifications in order to achieve even higher quality.

[Client Industries]

Camera module industry

[Target Application]

Actuator assembly.

+1-408-748-0100

+1-408-748-0100

Office Hours: 8:30am - 5:30pm PST